Anodising is one of the most popular ways to give aluminium a durable, decorative finish. But it can also be one of the trickiest. Many quality complaints we see at the Aluminium Federation (ALFED) come from commercial sheet, strip, or extrusions being used for anodising without the right specifications. This guide explains what you need to know to get it right, from surface quality to British Standards, and how defects can appear.

Why Some Anodised Aluminium Surfaces Look Flawed

When aluminium is extruded or rolled, its surface undergoes a smoothing process known as planishing. This makes the aluminium look perfect on the surface, but beneath, there may be hidden imperfections. These could include:

- Variations in grain structure

- Tiny alloying element precipitates

- Minor scratches or inclusions

The planished layer hides these flaws, so you might not notice them immediately. But here’s the catch: during anodising, the chemical treatment removes this smooth layer, exposing the substrate, and any imperfections.

How Anodising Highlights Imperfections

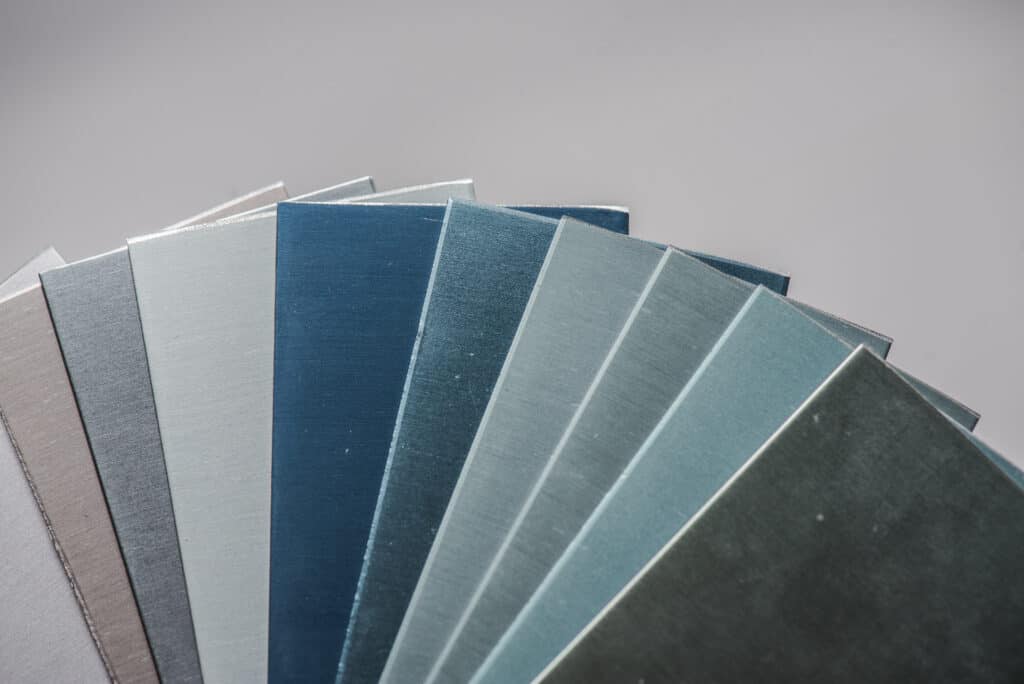

Anodising works by electrolytically growing an oxide layer on the aluminium surface. This layer is transparent, so any flaws in the substrate become visible. If the anodised aluminium is coloured, those flaws stand out even more.

This is why it’s so important to specify your aluminium correctly before it’s anodised. Otherwise, minor imperfections can suddenly become major visual defects.

Understanding British Standards

British Standards give us a clear framework for specifying anodising-ready aluminium:

- BS EN 485-1 – for sheet and strip

- BS EN 755-1 – for extrusions

Key points:

- Declare your intent: Suppliers need to know the aluminium is intended for anodising, especially decorative finishes.

- Agree limiting samples: These are reference pieces showing the acceptable level of surface flaws.

- Identify surfaces to be treated: Drawings should mark which areas will be anodised.

- Pre-delivery tests: Suppliers should perform anodising trials to check surface quality before shipping.

Following these steps ensures the anodised finish meets expectations and avoids costly complaints.

Typical Surface Flaws You Might See

Even with good specifications, some flaws are unavoidable. Here are the most common ones we see after anodising:

For Extrusions

- Porthole Grain Flow – Shows as light bands across the extrusion.

- Pressure Bands – Grain flow from web sections creates bands along the extrusion.

- Variable Grain Size – Incorrect extrusion temperatures can produce streaks.

- Micro-Alloy Segregation – Alloying elements can cause contrast in colour.

For Sheet and Strip

- Precipitate Drag-Tails – Resulting from incomplete homogenisation, common in 6XXX and 7XXX alloys.

These defects are usually not structural issues—they’re surface appearance issues. But for decorative anodising, appearance matters, so they must be managed.

Getting Your Purchase Order Right

To minimise defects:

- State clearly that the aluminium is intended for anodising.

- Include limiting samples to define acceptable surface quality.

- Mark visible and treated surfaces on drawings.

- Agree on pre-delivery anodising tests with your supplier.

Being proactive here saves headaches later and ensures a consistent, high-quality anodised finish.

Key Takeaways

- Planished aluminium surfaces hide imperfections that anodising exposes.

- Minor surface flaws are unavoidable but manageable with proper specification.

- Always declare your anodising intent and provide limiting samples to suppliers.

- Understanding typical defects helps avoid quality complaints.

By following these guidelines, you can achieve the decorative anodised finish your business expects, without surprises.